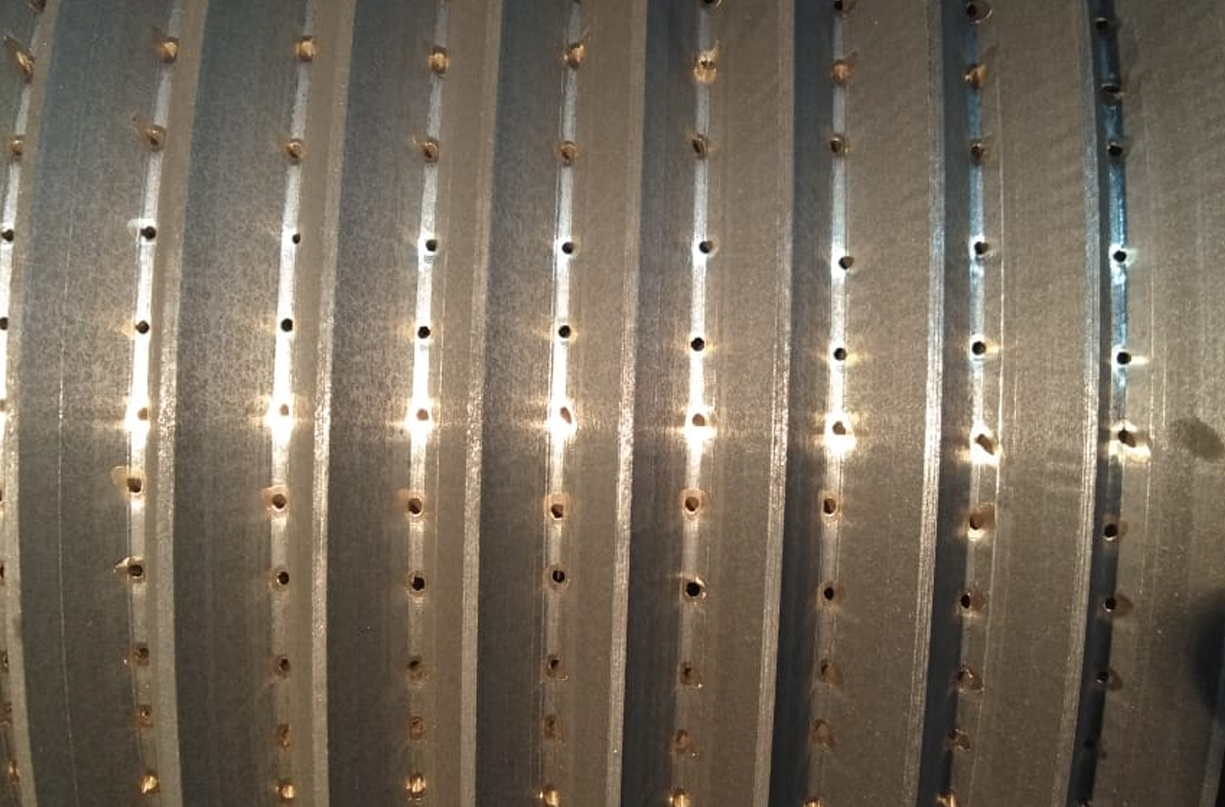

It has more than two thousands perforation at the face of Roller which elimenates reabsorption phenomenon completely.

Benefits :

- Grinding capacity increased by about 30%. This is limited by other

factors such as boiling house capacity etc. We are sure that perforated

Roller can increase the capacity of a Mill unit by upto 50%.

- The Bagasse moisture is reduced by 4 to 8 points.

- Increased Juice extraction by 20% at the perforated Roller Mill On

heavily

loaded mills the extraction had increased by 30%.